KAMA - tradiční český výrobce kvalitního pleteného oblečení

Fandíme hokeji

v retro dresu ČSR

S láskou k přírodě

Zážitky

Prodloužený

lyžařský

svetr

Nová pletená mikina

Nová

jednobarevná

sukně

Merino

šaty

Prodloužený

kulich

Věrnostní program

KAMA klub

Klasické vlněné svetry

Plastický dámský

oversize svetr

Olympijská kolekce

ANDORRA

Čistá radost

Celoroční vlněné svetry

V jednoduchosti je síla

Klasika,

na které to kdysi

všechno začalo

Do města i na hory

Prodloužená mikina

s kapucí

Město nás baví

Pro každou příležitost

Naše vlna nekouše

Vodoodpudivé Merino

Láska

na první pohled

KAMAKADZEEE

Pro ni i pro něj

Pletené

teplo domova

MERINO

ničím nenahradíš

Chyť a pusť

KAMA KIDS, kdo je víc?

Posouvejte své limity!

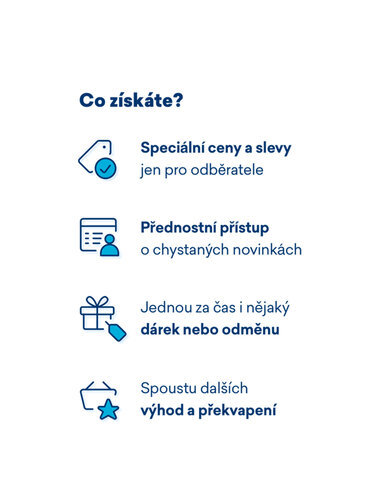

Výhody

Naše výrobky jsou nejen kvalitní a originální, ale měly by vám přinášet i dobrý pocit. Zjistěte proč.

Již 34 let vyrábíme srdcem nejen na hlavu

Přijměte pozvání do naší rodiny

Zakázková výroba

Staňte se součástí našeho příběhu

23/24